Wave Spring Application Examples

Wave spring technology is the trusted solution across many industries for a variety of applications. Engineers in the Aerospace, Automotive, Medical, Off-Highway, and Oil & Gas industries are just a few of those who have specified Smalley Wave Springs.

From everyday consumer products like the smartwatch on your wrist, or the coffee maker in your kitchen, to an oil well deep under the Earth’s surface, to as high as, well, Mars, there is virtually no limit for wave springs.

The wave spring advantage is in its ability to provide the same spring force as a traditional coil spring but at a reduced operating height. What this means for you is a more compact and light-weight assembly, saving you production time and material costs.

From small to large diameters, light to heavy-duty parts, carbon steel to exotic materials, wave springs are versatile enough to be utilized in over 25,000+ applications. We have 5 standard types of wave springs, hundreds of configurations, and several thousands of standards in stock. If a standard doesn’t fit your application requirements, we offer economical prototypes and No-Tooling-Costs™.

If you’re ready to transform your designs with a wave spring, get started with a Smalley engineer and request free samples.

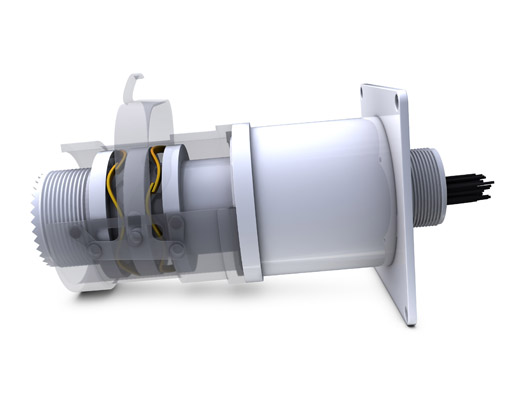

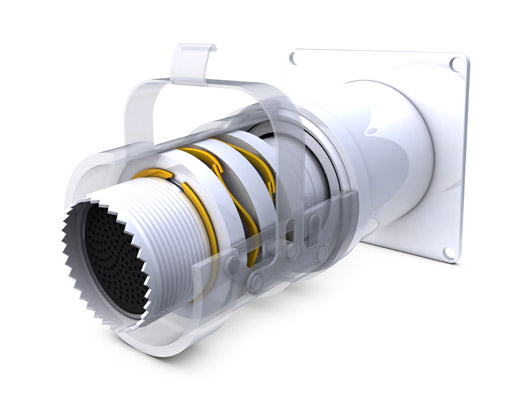

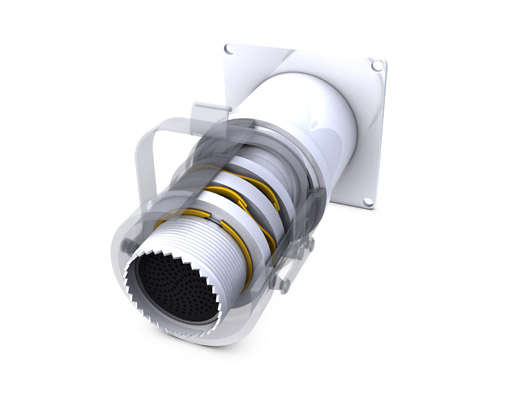

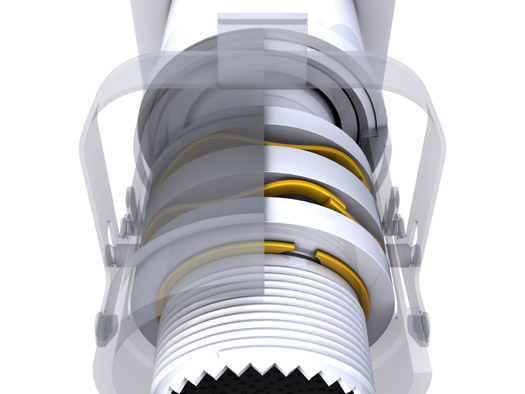

Aerospace Electrical Connector

The two Single-Turn, Overlap Type Wave Springs in the assembly exert a constant force on the connector when they are compressed providing the assurance of continuous connection.

Flow Valve Application

As fluid pressure increases the Crest-to-Crest Wave Spring precisely controls the linear displacement of the piston, which positions the orifice for proper fluid flow.

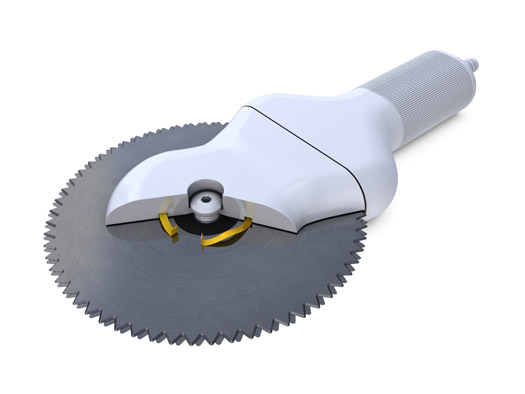

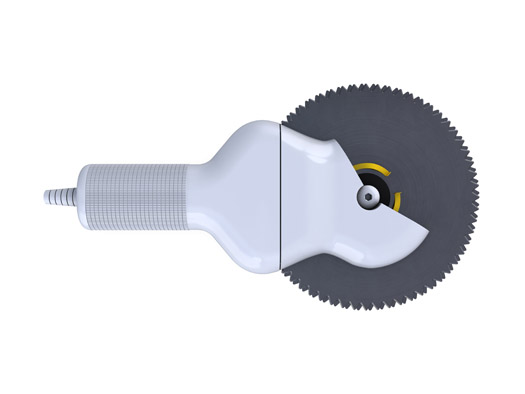

Multi-Tooth Cutter

The cutter uses a specially designed Wave Spring manufactured with locating tabs. The Wave Spring applies pressure to the two cutter halves, holding them together, while allowing them to oscillate.

Pressure Relief Valve

An exact pressure is accomplished using a Crest-to-Crest Wave Spring. Air pressure under the assembly causes the spring load to increase, forcing the plate away from the sealing surface providing the pressure relief mechanism. When the load against the spring decreases, the spring’s force decreases, allowing the unit to seal once again.

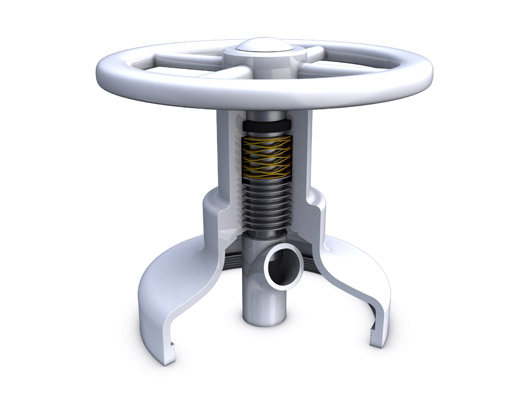

Valve

When compressed air is forced through the valve, the Crest-to-Crest Wave Spring compresses to accurately maintain a force that will precisely regulate the flow from the valve.

Water Valve

A Smalley Crest-to-Crest Wave Spring, also known as a Flat Wire Compression Spring, prevents the valve handle from undesired rotation by maintaining a constant load and engaging the threads on the main shaft. As the valve handle rotates, the wave springs' resistance increases, maintaining the valve position. Watch the video below.

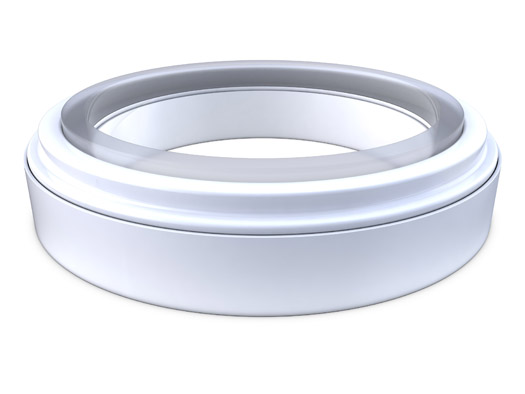

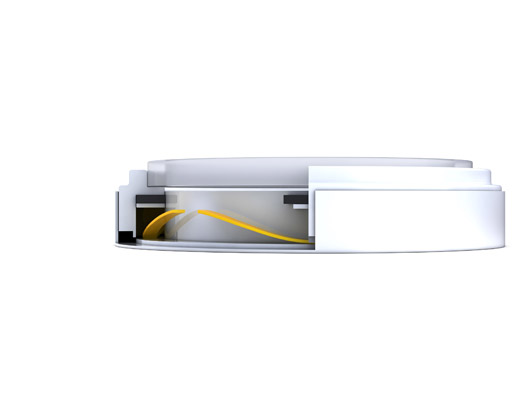

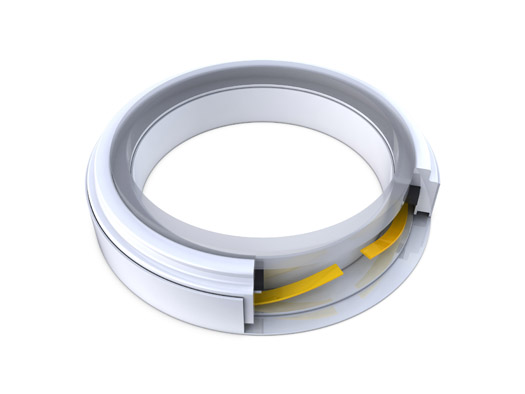

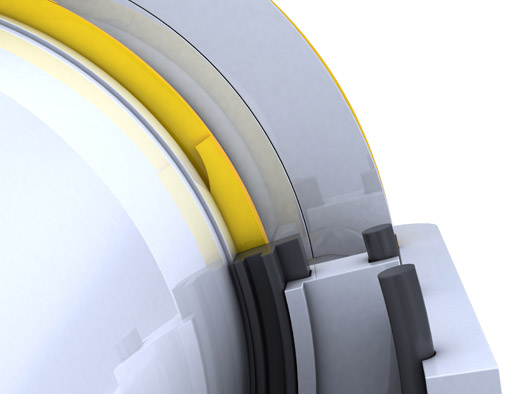

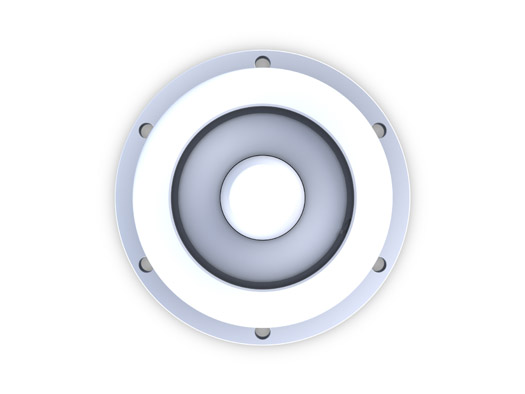

Face Seal

The Smalley Wave Spring applies pressure to precisely load the carbon face against a mating surface, properly sealing fluids. The wave spring operates over a fixed working range and provides an exact force. The Wave Spring replaces a stamped wavey washer that was unable maintain the necessary spring rate. The exact pressure of the carbon face against the sealing surface provided by the Wave Spring is essential to avoid excessive wear, yet maintain a proper seal.

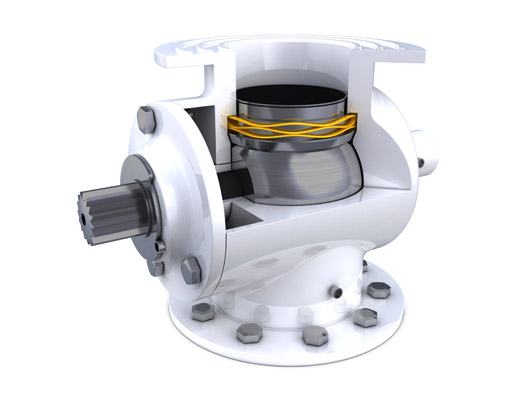

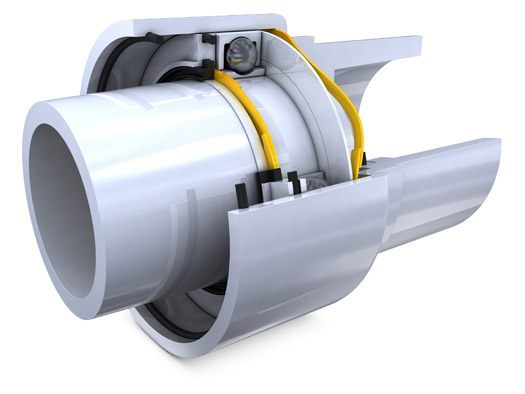

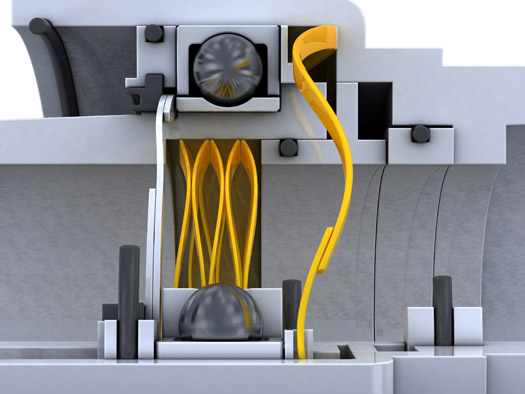

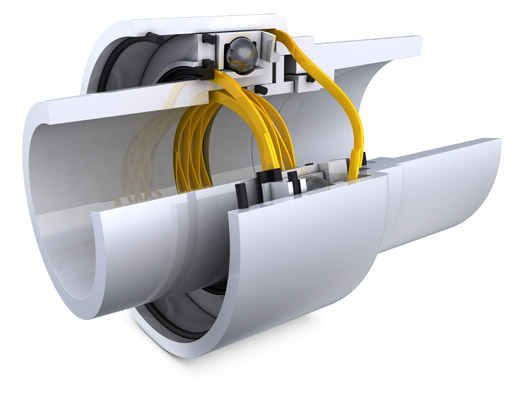

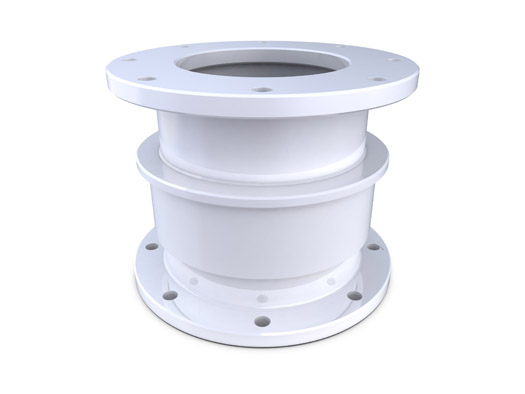

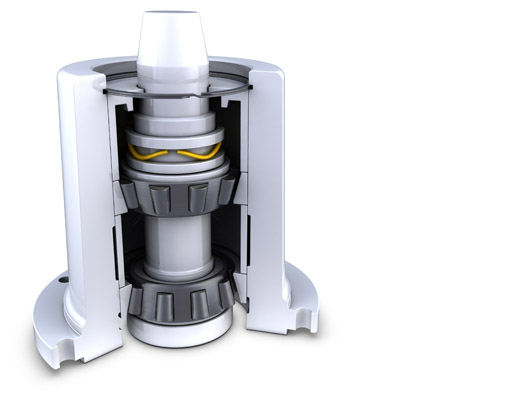

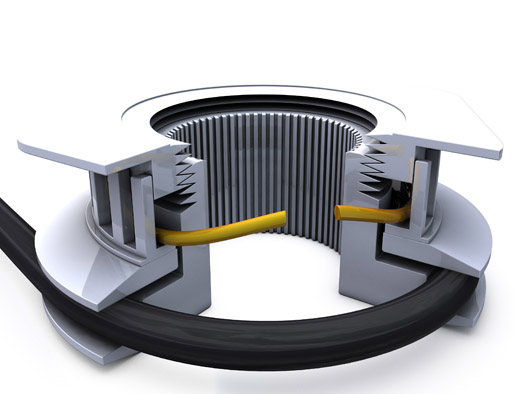

Rotary Union

This application incorporates both a Single-Turn and a Crest-to-Crest Wave Spring. The union cross section of the Wave Spring allows it to be installed in the assembly without interfering with mating components. The single turn wave spring takes up play and reduces vibration in a bearing preload capacity. The force of the Crest-to-Crest Wave spring, when compressed, helps create a seal to prevent fluid from flowing from the high pressure to the low pressure side of the union.

Vibration Isolator

Under constant loading, the isolator dampens vibration from equipment operation. Wavo Springs are used to provide the precise and predictable load/deflection curves.

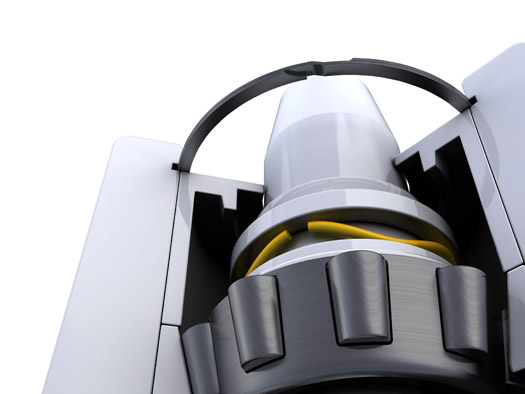

Axial Piston Pump

A Smalley Wavo Spring was specified to provide a higher preload to the tapered roller bearings. The Wavo was chosen since the force needed was greater than offered with a stock Wave Spring.

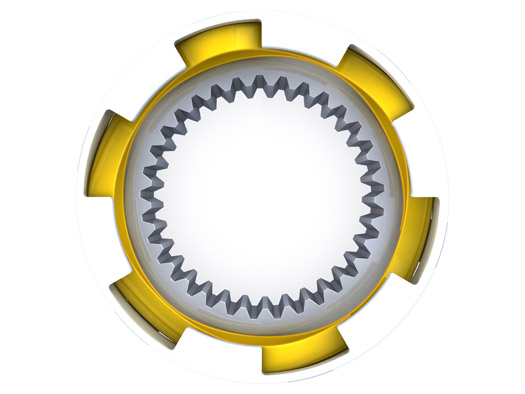

Floating Gear

Functioning in a contained bracket, a Smalley Crest-to-Crest Wave Spring loads the gear with light, yet accurate force allowing axial movement. The gear shown in this application self-aligns with its mating gear during operation.

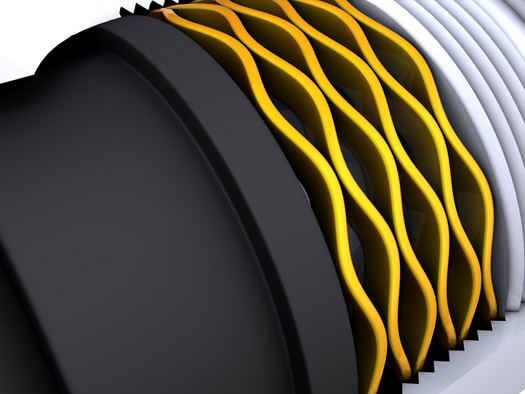

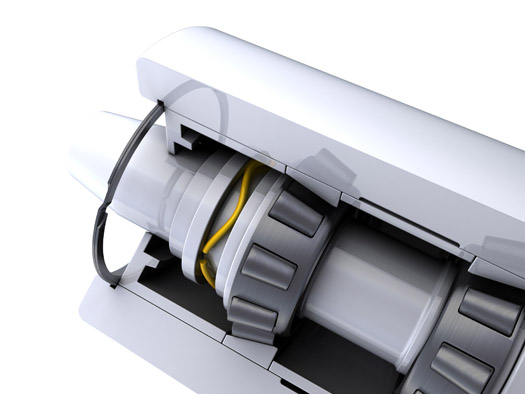

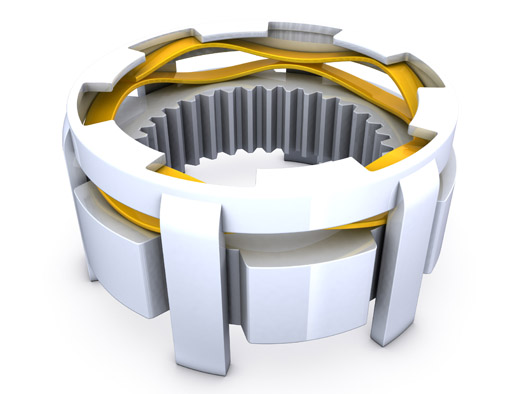

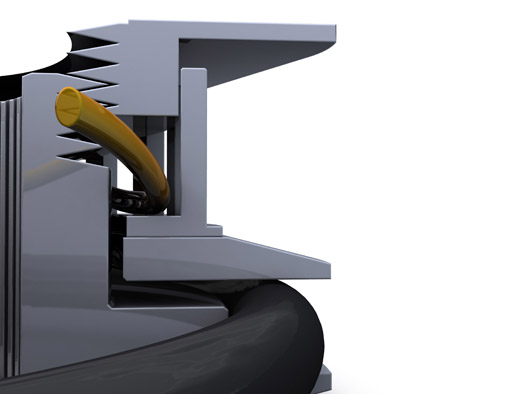

Clutch Drive

Pressure on the round belt is produced by compressing the Wavo Wave Spring through the sheave halves. The top threaded cap rotates to adjust the Wavo compression.

Connect With Us