Non-Standard Materials

OVER 40 CUSTOM MATERIALS FOR WAVE SPRINGS AND RETAINING RINGS

SUPER ALLOY

Smalley offers super alloys when carbon and stainless steels do not meet an application's unique requirements. Super alloys maintain material properties in extreme operating conditions. These materials exhibit no magnetism and can be blue, brown, or silver in color.

Materials may be heat treated in open-air or in an atmosphere-controlled furnace. Open-air heat treatment may produce scale, which often results in a dark residue. An atmosphere-controlled environment eliminates scale and produces a part with a brighter finish.

INCONEL®1 X-750

Inconel X-750 is a nickel-chromium alloy and precipitation heat treated to a spring temper condition. In this state, it has temperature resistance up to 700˚ F. Additional temper methods are available to achieve slightly different physical properties. Smalley also offers NACE (The National Association of Corrosion Engineers) approved materials to meet your requirements. This nickel-chromium alloy is used most commonly in high temperature and corrosive environments. Two commonly specified tempers of Inconel are described below.

- Rings and springs manufactured from this grade of Inconel have a blue/silver-gray color and exhibit no magnetism.

A286 ALLOY

A286 is a nickel-iron-based alloy that exhibits similar properties to Inconel X-750, but with additional heat resistance of up to 1000˚ F. Its spring temper condition is obtained by precipitation hardening.

- This material exhibits no magnetism and has a blue/silver-gray color.

ELGILOY®2

Elgiloy is a cobalt-based alloy known for its high strength and excellent corrosion resistance. It can be used in environments up to 800˚ F. Elgiloy shows improved resistance to sulfide stress cracking over other NACE-approved materials.

- Elgiloy exhibits no magnetism and is blue-brown in color as a result of heat treatment.

MP35N®3

MP35N is a nickel-cobalt-based alloy known for its high strength and corrosion resistance. It can be used in environments up to 600˚ F. It is often specified for oil and gas applications.

HASTELLOY® C-276

Commonly used in chemical processing industries, Hastelloy C-276 is a nickel-based alloy with proven performance in corrosive applications. Similar to other nickel-based alloys, it is ductile, easy to form, and has excellent resistance to stress corrosion cracking in chloride solutions. It can be used in environments up to 750˚F.

MONEL®1 K-500

Monel K-500 is a nickel-copper-based alloy known for its excellent corrosion resistance, strength, and hardness properties. It can be used in environments up to 550˚ F.

1 INCONEL X-750 and MONEL are registered trademarks of Special Metals Corporation.

2 ELGILOY is a registered trademark of Combined Metals of Chicago.

3 MP35N is a registered trademark of SPS Technologies Inc.

4 HASTELLOY is a registered trademark of Haynes International.

COPPER

When magnetism or conductivity is important to your application, Smalley offers a range of copper materials as a custom material option.

BERYLLIUM COPPER ALLOY # 25

Beryllium copper is nonmagnetic and one of the most electrically conductive materials offered by Smalley. Normally specified in a hard temper, it has a combination of low modulus of elasticity and high ultimate tensile strength. The alloy gains its physical properties by precipitation hardening. In contrast to other copper alloys, beryllium copper has the highest strength and is suitable to use at temperatures up to 400˚ F.

PHOSPHOR BRONZE, GRADE A

Phosphor bronze is a nonmagnetic alloy with fair electrical conductivity. It is purchased in a spring temper condition to maximize spring characteristics and can be hardened only by cold working. Phosphor bronze exhibits fair spring properties and is rated a step below beryllium copper in performance.

ADDITIONAL MATERIALS

In addition to the materials listed above, Smalley offers 410 Stainless Steel, Waspaloy, and others. If you have questions about these materials or do not see your desired material listed, please contact Smalley Engineering for more information.

HELPFUL LINKS

- Contact a Smalley Engineer to determine the best material for your application

- View Materials Table for more specifications on our common materials

- Read Blog: How to Control Corrosion: Material Selection for Rings and Springs

- Read EBook: Material Selection Guide

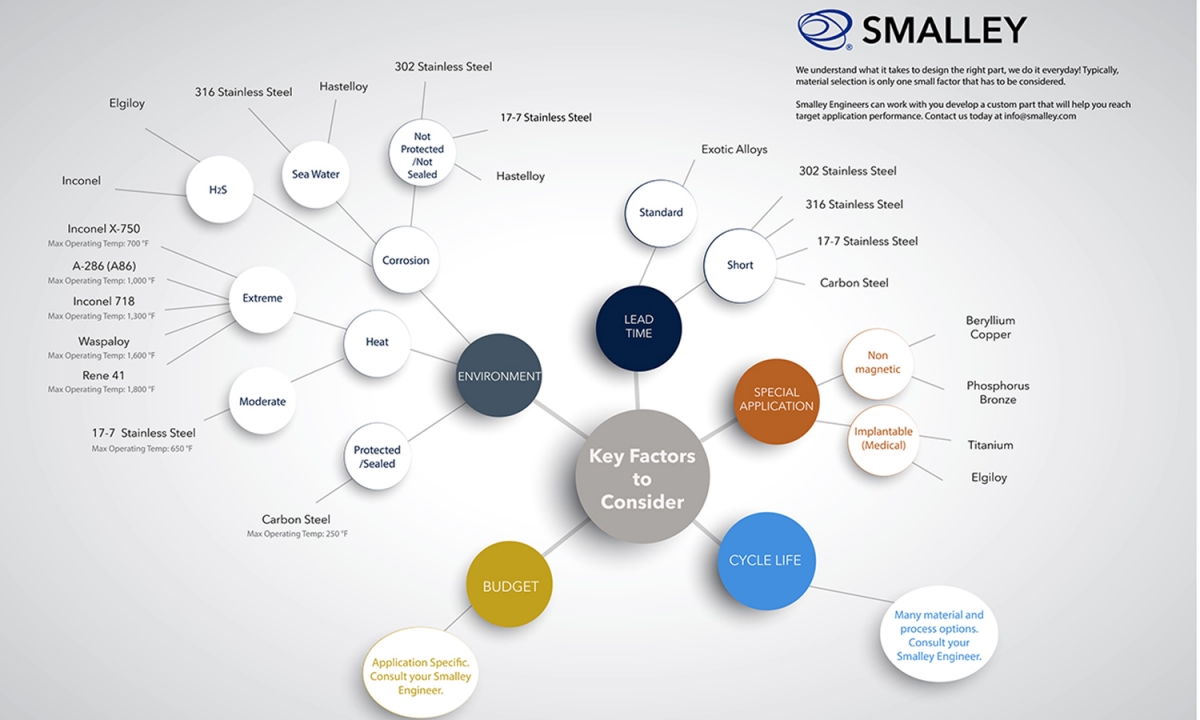

INFOGRAPHIC: KEY FACTORS TO CONSIDER WHEN SELECTING RING AND SPRING MATERIAL

Connect With Us