Understanding Wave Springs: Key Factors Influencing Compression Force

Wave springs are a versatile type of spring with a unique design. They offer a more compact solution than a coil spring for applications requiring some form of loading. In this Ask the Expert blog, we'll delve into the factors influencing the force a wave spring can output.

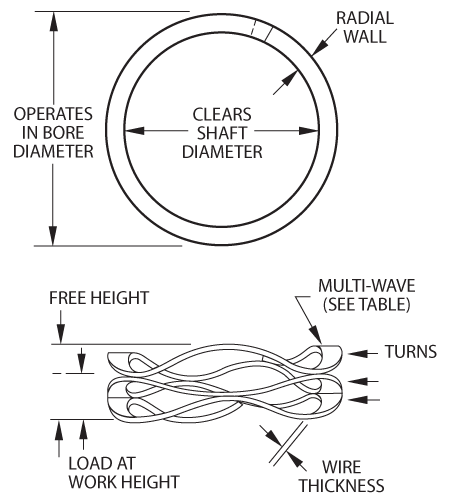

Wave springs are characterized by their wavy design, allowing them to compress and expand within a reduced space. This makes them ideal for applications where size and weight constraints are important. Structurally different from coil springs, wave springs have their own parameters influencing their compression force.

Factors Influencing Maximum Compression Force of a Wave Spring

1. Material Properties

- The choice of material significantly impacts a wave spring's performance. Materials with higher tensile strength and fatigue resistance can handle greater compression forces. Check out our more common materials in our Materials section.

2. Geometry and Design

- Wire Thickness: The thickness of the wire used in constructing the wave spring impacts its stiffness and, consequently, the compression force it can handle.

- Radial Wall: Although it does not influence the compression force as much as wire thickness, the radial wall contributes to spring stability, which is needed to carry heavier loads.

- Number of Waves: The number of waves in the spring design influences its overall flexibility and load-carrying capacity.

- Wave Height: The height of the waves determines the amplitude of deflection, affecting the compression force. Taller waves generally result in higher forces.

3. Dimensions

- Outside and Inside Diameters: The overall size of the wave spring, including both outside and inside diameters, affects the available space for compression. Engineers must consider these dimensions in relation to the application requirements.

- Free Height: The uncompressed height of the wave spring, known as the free height, is a contributing factor to the available travel distance for compression.

- Bore and Shaft (Cavity Size): Limiting factors such as the size of an application’s cavity (where the spring will be placed) are also essential to consider.

Additionally, the application requirements and environmental conditions may influence the design considerations.

Contact our Engineers

Do you require assistance finding the right Wave Spring for your application? Our dedicated engineers can review the specific requirements of your application to ensure that the selected Wave Spring meets the desired force and deflection characteristics while operating within its specified limits. With your design parameters in mind, we can determine what maximum load can be achieved on our Wave Springs. Please get in touch with us today to learn more information!

Connect With Us