What is a Retaining Ring? Smalley's Retaining Ring, Snap Ring, and Circlip Overview

Nails, Screws, Nuts, Bolts, Pins- the List Goes On. What Do These All Have in Common?

They hold things together. When you staple a piece of paper or hang a painting on a wall, you’re joining two things together through the means of a fastener.

So if we have many different types of fasteners, how do I know which one to use?

Figuring out which fastener to use goes back to the application.

Factors like the environment it’s exposed to, ease of installation, material or weight limitations, cost, aesthetics, and reusability should all be taken into consideration.

Here at Smalley, we manufacture retaining rings. So what is a retaining ring and when should I use it?

What is a retaining ring?

A retaining ring is a type of industrial fastener that holds mating components or assemblies together.

A retaining ring is a circular component made out of metal that sits in a groove (housing or shaft).

You can have an internal (housing) retaining ring or an external (shaft) retaining ring. As the name suggests, an internal ring sits in a housing groove, whereas an external ring sits in a shaft groove.

Internal External

Why Would You Use a Retaining Ring?

A retaining ring functions as a removable shoulder.

Used as an alternative to machining a shoulder, retaining rings eliminate complex machining processes, ultimately saving time, weight, and production cost for a more efficient production process.

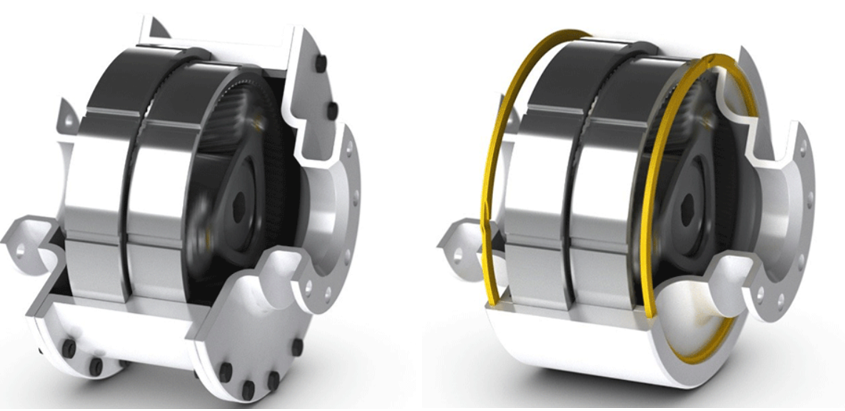

A retaining ring can also streamline your assembly. A single retaining ring can replace multiple bolts on a gear assembly, eliminating the need for drill and tapping holes while also simplifying the installation process, and therefore time. Two dozen were replaced by two Spirolox retaining rings in the gearbox assembly pictured below.

Why would you use a Spirolox Retaining Ring over other rings?

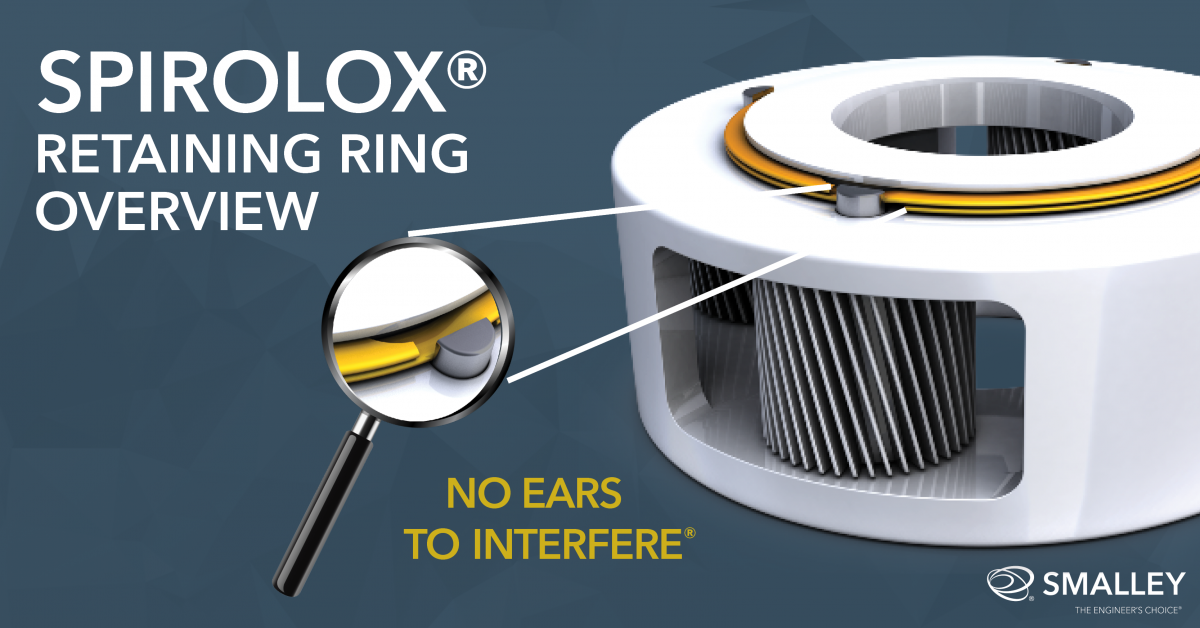

While there are other types of rings available, engineers specify Spirolox retaining rings because of their low radial profile, reliability, and convenience.

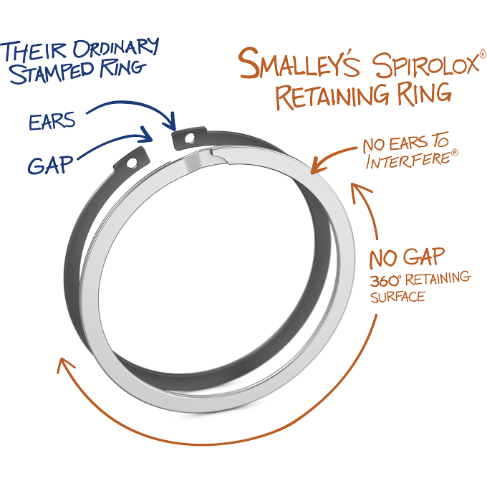

An advantage of using a Spirolox retaining ring, also known as a spiral retaining ring, in your application is its unique configuration. Traditional snap rings have ears, or so-called lugs. Since Spirolox rings have No-Ears-to-Interfere®, they will smoothly integrate with mating components with a low radial profile. They have a uniform cross-section and are more aesthetically pleasing.

They also have no gap, so they provide a 360° retaining surface for even load distribution while securely holding the mating component in place.

Lastly, they are easy to install and remove in comparison to other rings, which require snap ring pliers. Spirolox rings can be installed by spiraling the ring into the groove and have a removal notch for simple removal with no special tools.

For a more detailed explanation of the advantages of using a Spirolox retaining ring, read our Retaining Ring vs. Circlip blog.

How is a Retaining Ring Made?

Now that you know what a retaining ring is and why it’s used, we’ll go over how a retaining ring is made.

Smalley Spirolox retaining rings are made by edgewinding, the only manufacturing process we trust to deliver precise yet flexible solutions.

Snap rings are traditionally stamped out of sheet metal, as seen in the image below.

Smalley’s edgewinding process works by taking flat wire and coiling it on edge. What this means for you is quickly and economically manufactured rings.

Stamping a ring produces excess scrap from the center, which is especially important for expensive materials and large diameters. Because no material waste is produced during edgewinding, custom materials become more economical.

Another benefit of our edgewinding, No-Tooling-Cost process is design flexibility. When stamping a custom ring, additional tooling costs are necessary to cover any new punches and dies, often with long lead times. Whether it’s a prototype or production run, we are quickly and easily able to make modifications during any stage of the process, so custom rings get delivered fast and with No-Tooling-Costs™.

Where are retaining rings used?

Smalley engineers have worked on over 25,000 applications. From the watch dial on your wrist to a wind turbine, few applications are too small or too big for a retaining ring to secure.

They’re found in virtually every industry, and you probably didn’t even know they were there.

When you’re at your annual checkup, you’ll find rings inside various medical equipment at the doctor’s office. When you drive your car, you’ll find our rings inside the transmission that allow it to function on a daily basis. When you’re flying in a plane, there’s a retaining ring in the engine when you’re going on vacation.

Here at Smalley, our team of engineers has the industry expertise to meet your unique application requirements.

Are there different types of retaining rings?

From light to heavy-duty, we have over 6,000 standard retaining rings broken down into 30 configurations. Single and multiple turn rings are available, depending on the type of load required. Standard sizes range from 1/4 in. to 16 in., or 6 mm to 400 mm in both carbon and stainless steel. If you’re using a traditional snap ring, our retaining rings can be used as a groove interchange. View our Interchange Listing parts table for a complete list.

There are 5 main types of retaining rings: Single-Turn Spirolox Retaining Rings, Multiple-Turn Spirolox Retaining Rings, Constant Section, Hoopster, and WaveRing.

Each type of ring use case is described below. For a more detailed explanation of the different types of rings we offer, read our Retaining Ring Types blog.

Custom rings such as ID/OD lock, self-lock, and balance are also available.

What Materials/Finishes Do You Have for a Retaining Ring?

Standard Spirolox® retaining rings are available in Carbon Steel, 302 and 316 Stainless Steel, while Constant Section Ring (snap rings) and Hoopsters are available in Carbon Steel and 302 Stainless Steel.

Retaining rings can be produced in a variety of custom materials to meet unique environmental conditions. Take a look at our Material Selection Guide, and consult with a Smalley engineer to find the appropriate material for your retaining ring to maximize performance.

Our carbon steel retaining rings are dipped in oil to prevent corrosion during delivery. Additionally, we offer various types of platings and coatings to meet your application requirements. Black oxide, zinc phosphate, and cadmium plating are a few common types of finishes.

Get Started:

-

What ring is best for your application? Our engineers are here to help! Submit your Application Requirements

-

Try out the Spirolox Retaining Ring advantage for yourself. Request Free Samples

Interested in learning more?

We've put together a FAQ Retaining Ring E-Book for you.

Connect With Us